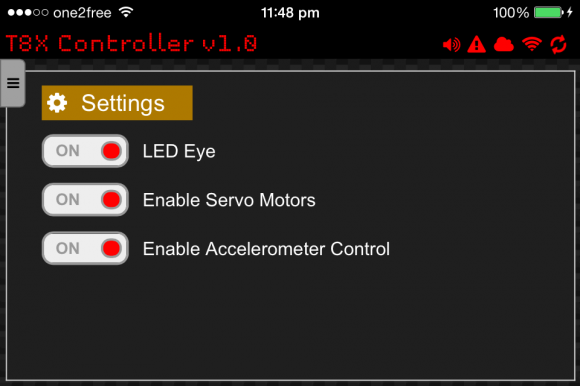

As some of you have asked us by email, “Is a controller included?”. The short answer is no. The long answer is that we’re including an app, and today, we’re revealing the news! Instead of physical joysticks, we have moved the entire controller into the digital world by creating an app that takes advantage of your smartphone’s or tablet’s touch screen display to move the spider around. This also allows users to easily download and run pre-programmed scripts at the touch of a button. Most importantly, the flexibility of a software based controller means that it is customizable and can be updated to newer versions as they become available in the future.

The app is compatible with virtually any WiFi enabled device, including iOS and Android and is included with the product.

Modified Injection Molds

For the past two months, we’ve been secretly redoing the injection molds. Injection molds are one of the most time consuming and expensive stages of product development, but from a quality point of view, it’s been worth it. Some of the changes include upgrading the molds from a standard grade steel to a high quality imported steel and using high quality imported raw plastic materials. This allows the plastic components to be manufactured with much tighter tolerances for smooth and energy-efficient walking. Appearance-wise, we simply had to get rid of the distracting gaps for screw mounts on the legs and tail, which took away biological realism from the creature.

Manufacturing Preview

Our most recent machine addition to our lab is an automated Pick and Place machine, which accurately assembles tiny electronic components onto a printed circuit board at a high production speed. All boards are manufactured in-house, giving us complete control over the quality of our products.

A Spider House

The T8X deserves a good home when not in use, so, as mentioned in our status updates, we’re putting extra thought into the box design.

Of all the types of protection methods available, from Styrofoam to bubble wrap to vacuum-formed packaging and so on, we have found that polyurethane foam provides the best possible protection. Here’s a sneak peek. The final box look will be revealed in our next update.

The shape of the foam is tailor-made to fit the T8X robot, providing the robot a snug fit during transport. Battery and power adapter compartments are also included for convenience.

During the foam manufacturing process, we discovered a new species. Until we’re able to properly identify them, we are just calling them FoamBugs. These FoamBugs are everywhere! Although quite harmless, we haven’t figured out what to do with them yet.

Testing

At the heart of each of our walking robots is our Bigfoot™ Robotics Engine, a piece of software that turns lifeless mechanical parts, motors and electronics components into scary, life-like creatures. After new algorithms are developed, they are tested to make sure that they work just as intended.

To do this, we use grid environments to film and playback sequences of motions while keeping the robot stationary. This allows us to measure different parameters, such as walking speeds and leg motions in a controlled and measurable environment.

A new major update will be available in March. We also will be announcing the official launch date in the first week of March on our T8X product page’s Status Updates section. Stay tuned for more to come!

Run for your lives!!!